Osg Form Tap

Osg Form Tap - Because no chip is produced, breakage due to chip packing and bird nesting is eliminated. Form taps are ideally suited for both blind & through holes. 5 high performance form taps for up to 40 hrc! Web performance form taps for materials < 32rc. Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. Experience the performance of the world's no.1 tap market shareholder. Web x performer forming tap the xpf represents a new evolution in forming tap technology. Web these form taps generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 40 hrc and sizes up to or exceeding 1 in diameter. Web osg catalog | taps | end mills | drills | indexable | composite tooling | diamond coating | die products. Features fluteless forming tap produces no chips, making it up to 17x more durable than cut taps.

Features fluteless forming tap produces no chips, making it up to 17x more durable than cut taps. Web osg forming taps 1 2 3 4 5 msc #: 5 high performance form taps for up to 40 hrc! $37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. Because no chip is produced, breakage due to chip packing and bird nesting is eliminated. Form taps are ideally suited for both blind & through holes. Web x performer forming tap the xpf represents a new evolution in forming tap technology. This series is engineered to generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 35 hrc and sizes up to m45 in diameter. Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl.

Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. 4 variable helix tap for stainless steel. Web these form taps generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 40 hrc and sizes up to or exceeding 1 in diameter. Features fluteless forming tap produces no chips, making it up to 17x more durable than cut taps. Web osg forming taps 1 2 3 4 5 msc #: $37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. Experience the performance of the world's no.1 tap market shareholder. Web osg catalog | taps | end mills | drills | indexable | composite tooling | diamond coating | die products. 5 high performance form taps for up to 40 hrc! Web x performer forming tap the xpf represents a new evolution in forming tap technology.

OSG Cobalt Plug Thread Forming Tap 3/410 H10 CrN 1400154806 Dan's

Web osg forming taps 1 2 3 4 5 msc #: Web osg catalog | taps | end mills | drills | indexable | composite tooling | diamond coating | die products. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl..

OSG 3/824 UNF Modified Bottoming Thread Forming Tap 09833732 MSC

Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. This series is engineered to generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 35 hrc and sizes up to m45 in diameter. Web osg catalog | taps |.

OSG Modified Bottoming Spiral Thread Forming Tap 5/1618 H6 PM TiCN

Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl. $37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. Experience the performance of the world's no.1 tap market shareholder. Because no chip is produced, breakage.

OSG CANADA, LTD. EXOTAP® NRT® Premium Forming Taps TGO359 (1405007608

Web performance form taps for materials < 32rc. Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl. 4 variable.

OSG Cobalt Modified Bottoming Thread Forming Tap 3/824 H4 TiN

Web performance form taps for materials < 32rc. Web these form taps generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 40 hrc and sizes up to or exceeding 1 in diameter. Experience the performance of the world's no.1 tap market shareholder. This series is engineered to generate up to 50%.

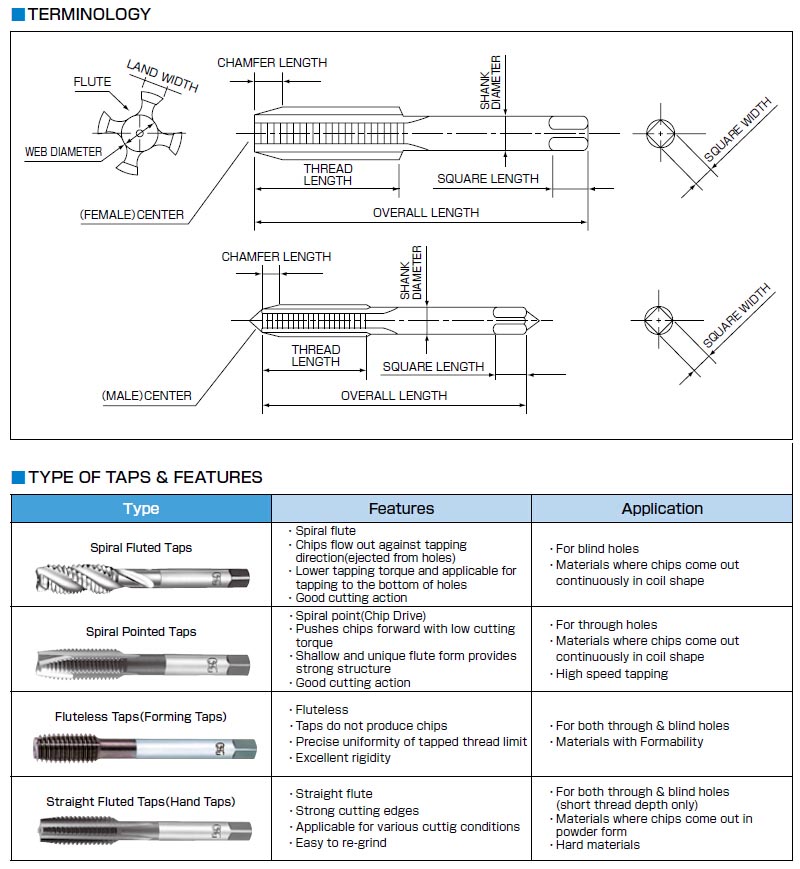

OSG TAP TERMINOLOGY

Web x performer forming tap the xpf represents a new evolution in forming tap technology. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl. $37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. Experience.

ボード「Taps」のピン

This series is engineered to generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 35 hrc and sizes up to m45 in diameter. Web performance form taps for materials < 32rc. Form taps are ideally suited for both blind & through holes. Web x performer forming tap the xpf represents a.

OSG 1/420 UNC Modified Bottoming Thread Forming Tap 07462666 MSC

Web these form taps generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 40 hrc and sizes up to or exceeding 1 in diameter. Web performance form taps for materials < 32rc. 4 variable helix tap for stainless steel. Osg cutting tools for threading applications. Because no chip is produced, breakage.

UB Bottoming Roll Form Tap M9x1 D7 HSS TiN (10 Pack) Dan's Discount Tools

Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl. Web these form taps generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 40 hrc and sizes up to or exceeding 1 in.

WORK MATERIAL TAP SELECTION CHART OSG UK Ltduk.· VPDCMT Straight

$37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl. Form taps are ideally suited for both blind & through holes. Experience the performance of the.

Web These Form Taps Generate Up To 50% Less Torque Versus Other Forming Taps, Making It Feasible To Tap Materials Up To 40 Hrc And Sizes Up To Or Exceeding 1 In Diameter.

Form taps are ideally suited for both blind & through holes. This series is engineered to generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 35 hrc and sizes up to m45 in diameter. Web osg catalog | taps | end mills | drills | indexable | composite tooling | diamond coating | die products. Product search list of products videos catalogs cad data prev next start stop collection spiral flute tap for blind holes / work materials that cause chips to curl.

Web Osg Forming Taps 1 2 3 4 5 Msc #:

Because no chip is produced, breakage due to chip packing and bird nesting is eliminated. Features fluteless forming tap produces no chips, making it up to 17x more durable than cut taps. Web x performer forming tap the xpf represents a new evolution in forming tap technology. Web performance form taps for materials < 32rc.

4 Variable Helix Tap For Stainless Steel.

Experience the performance of the world's no.1 tap market shareholder. $37.56 qty add to cart bottoming chamfers are used for threading blind holes to the bottom. 5 high performance form taps for up to 40 hrc! Web forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread.