Vacuum Form Material

Vacuum Form Material - Web vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. It lists most common vacuum forming materials, their basic properties in standard grade, some advice on costs & typical uses for formings made from each material type. These sheets enable creators to make molds in minutes instead of hours. Polycarbonate (pc) it is a good choice as it is virtually unbreakable, highly resistant, uv protected from one or both sides, half the weight of glass, and hence they are easy to install and handle in the machine. 4.2 out of 5 stars 35. Web vacuum forming can be used with a variety of thermoplastic materials, including abs, polycarbonate, and pvc, among others. Vacuum forming temporary splint material. Web vacuum forming is a manufacturing process by which a sheet of plastic is heated and pressed over a form to create a part. In this guide, we'll cover the best practices for achieving this using 3d printing. During the vacuum forming process, a sheet of plastic is heated and then pulled around a single mold using suction.

Casted or molded tools 3.3 3. So what are the best plastics for vacuum forming? Web 3 tooling materials 3.1 1. Web which of your sheets are commonly used for vacuum forming? Cnc machined aluminum and resin 4 application of vacuum forming 4.1 a) agricultural components 4.2 b) automotive parts 4.3 c) packaging 4.4 d) household items 4.5 e) retail and marketing displays 4.6 f) electronics Web vacuum forming can be done on a variety of thermoplastics but typically the materials that are used in vacuum forming are as follows: It lists most common vacuum forming materials, their basic properties in standard grade, some advice on costs & typical uses for formings made from each material type. This makes it a flexible process that can be adapted to a range of applications and industries. A specific risk is outgassing of solvents absorbed in plastics after cleaning. Web vacuum forming is a manufacturing method used to shape plastic materials.

4.2 out of 5 stars 35. Polycarbonate (pc) it is a good choice as it is virtually unbreakable, highly resistant, uv protected from one or both sides, half the weight of glass, and hence they are easy to install and handle in the machine. Web vacuum forming can be used with a variety of thermoplastic materials, including abs, polycarbonate, and pvc, among others. Web vacuum forming can be done on a variety of thermoplastics but typically the materials that are used in vacuum forming are as follows: These sheets enable creators to make molds in minutes instead of hours. Please order product based on its description. Web vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Web vacuum forming is a manufacturing method used to shape plastic materials. Dimensions are perfectly fitted for the vaquform dt2 digital vacuum former to avoid any leaking while vacuuming. A specific risk is outgassing of solvents absorbed in plastics after cleaning.

Vacuumed Formed Trays A.L. Plastics

Web materials may sublimate in vacuum (this includes some metals and their alloys, most notably cadmium and zinc). Dimensions are perfectly fitted for the vaquform dt2 digital vacuum former to avoid any leaking while vacuuming. View msds / sds [ + ] see my price. Web vacuum forming can be used with a variety of thermoplastic materials, including abs, polycarbonate,.

Mega Electronics 712033 White Vacuum Forming Sheets 305 x 520 x 1mm

Vacuum forming temporary splint material. Web vacuum forming can be used with a variety of thermoplastic materials, including abs, polycarbonate, and pvc, among others. Web materials may sublimate in vacuum (this includes some metals and their alloys, most notably cadmium and zinc). Web which of your sheets are commonly used for vacuum forming? Web vacuum forming material selection guide this.

Hardware Store Vacuum Table HOW TO make your own Punished Props Academy

4.2 out of 5 stars 35. The sheets are heated and then sucked down by applying a vacuum to the underside of the mould, atmospheric air pressure then forces the heated plastic to adopt the shape of the mould. Dimensions are perfectly fitted for the vaquform dt2 digital vacuum former to avoid any leaking while vacuuming. Web vacuum forming is.

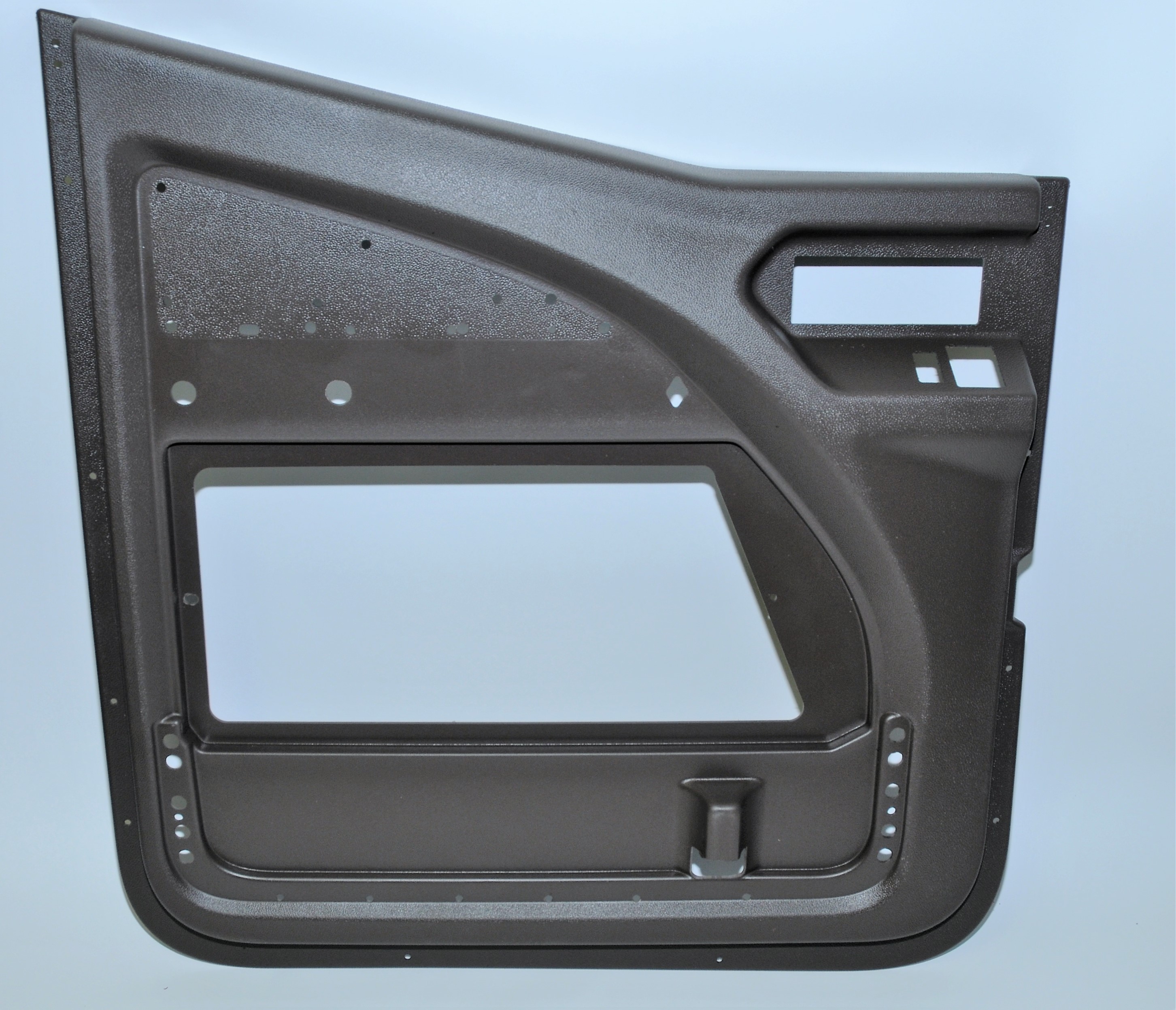

Vacuum Form superiortrim

The process is compatible with thermoplastics and thermoset materials despite their differences. Web annwah 20pcs dental vacuum forming splint sheets, thermoforming materials for vacuum forming machine 5'' x 5''(hard,1.0mm) 4.5 out of 5 stars 49. The sheets are heated and then sucked down by applying a vacuum to the underside of the mould, atmospheric air pressure then forces the heated.

Vacuum Form superiortrim

4.2 out of 5 stars 35. Web although simplified somewhat, vacuum forming is similar to thermoforming (which produces comparable results). Vacuum forming clear & bleach tray material. Web vacuum forming is a manufacturing method used to shape plastic materials. Please order product based on its description.

Vacuum Forming Company London Vacuum Formed Parts

Polycarbonate (pc) it is a good choice as it is virtually unbreakable, highly resistant, uv protected from one or both sides, half the weight of glass, and hence they are easy to install and handle in the machine. Dental laboratory laminate vacuum forming splint.030 (thin).8mm pack /25 proform. During the vacuum forming process, a sheet of plastic is heated and.

Vacuum Form superiortrim

Web vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. That way they can be heated, shaped and moulded without losing any of their inherent properties and each has their own particular merit of course. Or the gases can be released from.

How To Vacuum Form in 3 Easy Steps YouTube

View msds / sds [ + ] see my price. That way they can be heated, shaped and moulded without losing any of their inherent properties and each has their own particular merit of course. The sheets are heated and then sucked down by applying a vacuum to the underside of the mould, atmospheric air pressure then forces the heated.

Ultimate Guide to Vacuum Forming 3D Prints MakerBot 3D Printers

Web vacuum forming equipment & materials buffalo dental manufacturing company, inc. Web vacuum forming material selection guide this vacuum forming material selection guide is part of our free help with vacuum forming. The process is compatible with thermoplastics and thermoset materials despite their differences. In this guide, we'll cover the best practices for achieving this using 3d printing. Web although.

Plastic VacuumForming Sheets

Casted or molded tools 3.3 3. Web 3 tooling materials 3.1 1. Polycarbonate (pc) it is a good choice as it is virtually unbreakable, highly resistant, uv protected from one or both sides, half the weight of glass, and hence they are easy to install and handle in the machine. Web vacuum forming can be done on a variety of.

Web Vacuum Forming Material Selection Guide This Vacuum Forming Material Selection Guide Is Part Of Our Free Help With Vacuum Forming.

Vacuum forming clear & bleach tray material. Web annwah 20pcs dental vacuum forming splint sheets, thermoforming materials for vacuum forming machine 5'' x 5''(hard,1.0mm) 4.5 out of 5 stars 49. We are an authorized distributor for royalite, kleerdex, primex, plaskolite, lustro, cyro, spartech and more. A specific risk is outgassing of solvents absorbed in plastics after cleaning.

Traces Of Lubricants, Residues From Machining, Can Be Present On The Surfaces.

Dimensions are perfectly fitted for the vaquform dt2 digital vacuum former to avoid any leaking while vacuuming. Vacuum forming temporary splint material. Web vacuum forming equipment & materials buffalo dental manufacturing company, inc. Web although simplified somewhat, vacuum forming is similar to thermoforming (which produces comparable results).

Polycarbonate (Pc) It Is A Good Choice As It Is Virtually Unbreakable, Highly Resistant, Uv Protected From One Or Both Sides, Half The Weight Of Glass, And Hence They Are Easy To Install And Handle In The Machine.

Web vflex is an elastic thermoformable mold material meant to be used as an alternative to silicon. Cnc machined aluminum and resin 4 application of vacuum forming 4.1 a) agricultural components 4.2 b) automotive parts 4.3 c) packaging 4.4 d) household items 4.5 e) retail and marketing displays 4.6 f) electronics 4.2 out of 5 stars 35. In this guide, we'll cover the best practices for achieving this using 3d printing.

Web Vacuum Forming Is A Manufacturing Process By Which A Sheet Of Plastic Is Heated And Pressed Over A Form To Create A Part.

Casted or molded tools 3.3 3. This makes it a flexible process that can be adapted to a range of applications and industries. Web which of your sheets are commonly used for vacuum forming? Please order product based on its description.